June 16, 2025

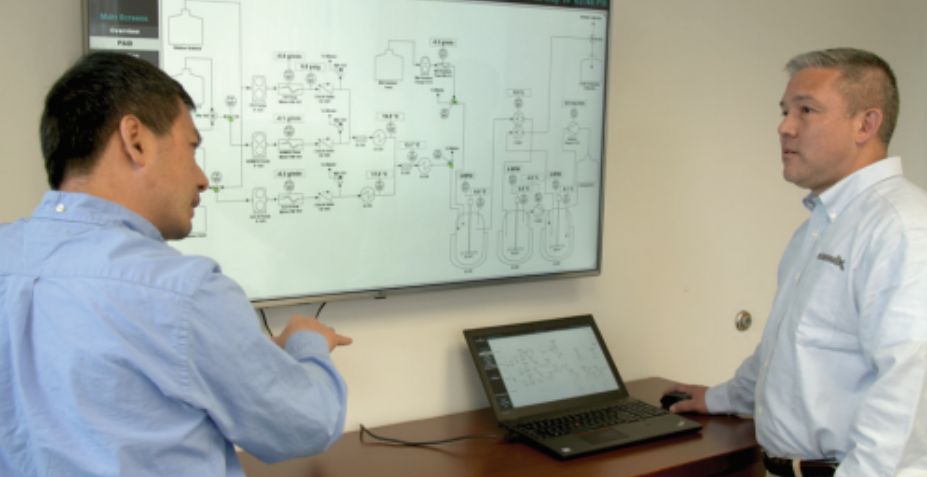

June 16, 2025 Why Upgrade to Ignition 8.1 Before Ignition 8.3

Key Takeaways for Ignition 8.1 Upgrade Projects Ignition 7.9 reached End-of-Life in June 2025 – no more support, increasing system risk. Ignition 8.1 is the…

Read Article