The Power of Modular PLC Code for Enhanced Performance, Reusability, Flexibility & Interoperability

This article was originally published on AutomationWorld.com on January 8, 2024.

Everyone loves spaghetti! Who doesn’t remember their grandmother cooking spaghetti, the aroma filling the house, the anticipation of a delicious, hearty meal? It’s a universal comfort food, often bringing back fond memories of family gatherings and cozy dinners. However, while spaghetti on your dinner plate is a delightful experience, ‘spaghetti code’ in the context of PLC programming is far less appetizing.

What is Spaghetti Code?

Spaghetti code – a term that brings a shiver down the spine of any PLC programmer or system integrator. This kind of code, characterized by its tangled, unstructured, and confusing nature, is the antithesis of what we strive for in automation software integration. It’s hard to follow, harder to debug, and a nightmare to modify.

But here’s the good news: with modular coding, one can avoid the tangle of spaghetti code and reap multiple benefits. Modular PLC code, with its structured and organized approach, not only enhances performance but also ensures reusability, flexibility, and interoperability – essential ingredients for a successful automation recipe.

The Benefits of a Modular Approach

Modular code refers to the practice of breaking down a program into separate, independent modules or components, each responsible for a specific functionality. There are several benefits to adopting a modular approach in coding:

- Code Reusability:

Modular code allows you to encapsulate functionality and reuse code across various parts of an application. Code is developed and tested once, increasing efficiency and quality. - Scalability:

Enhanced scalability by allowing new functionality without restructuring the entire code base. - Troubleshooting & Maintenance:

Modular components are easier to test and debug, ensuring that each component functions correctly before integration. - Integration & Interoperability:

By exposing only necessary information through well-defined interfaces.

Types of Modules to Replace Spaghetti Code

The S88 standard (ISA-88) provides guidelines and a modular framework for implementing batch control systems within the realm of PLCs. You shouldn’t relegate this approach to only batch processes as you can use it across a variety of both discrete and process industries.

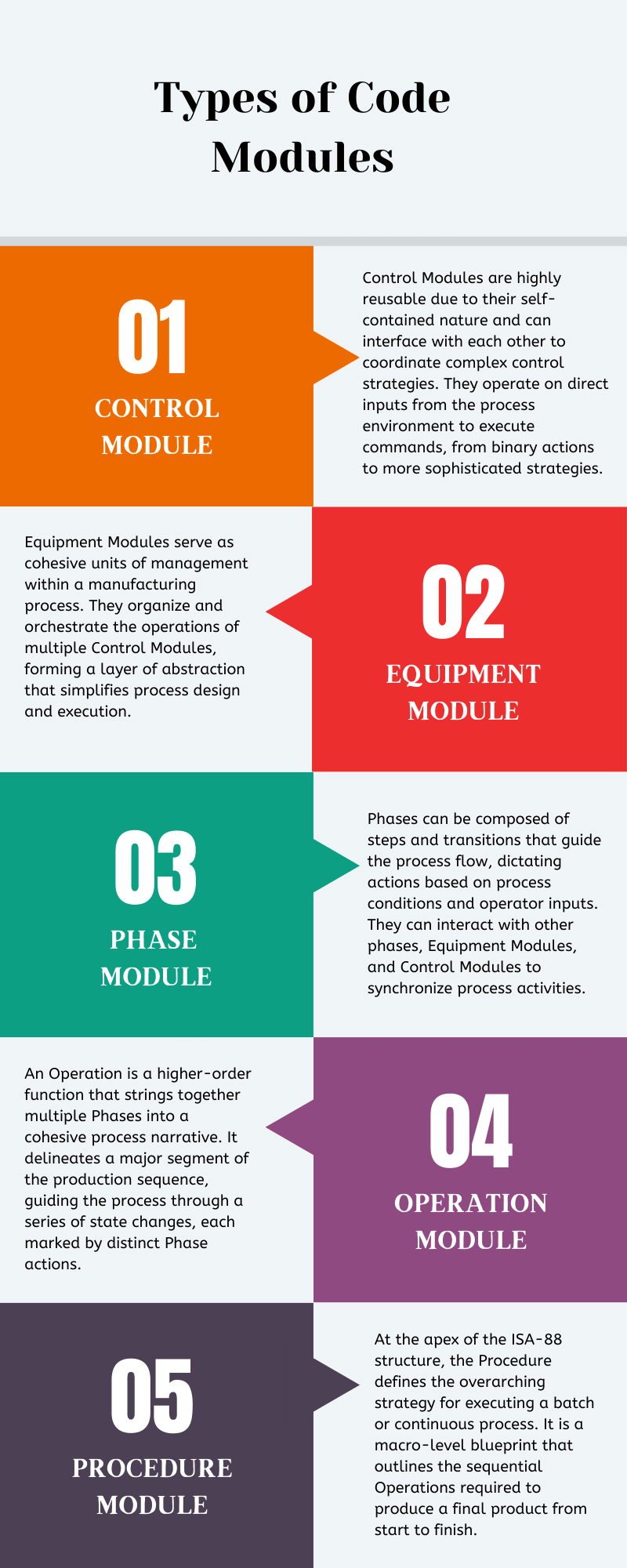

Control Module

Within the hierarchical structure of ISA-88, a Control Module represents the fundamental building block of process control. It executes the most elemental control actions directly on the plant floor. These modules encapsulate the logic required to operate individual pieces of equipment—such as actuators, sensors, and drives—and manage their basic behavior.

Control Modules are highly reusable due to their self-contained nature and can interface with each other to coordinate complex control strategies. They operate on direct inputs from the process environment to execute commands, which can range from the binary actions of opening or closing a valve to more sophisticated control strategies involving Proportional-Integral-Derivative (PID) algorithms that adjust parameters based on sensor feedback to maintain process variables within desired thresholds.

Equipment Module

Equipment Modules serve as cohesive units of management within a manufacturing process. They organize and orchestrate the operations of multiple Control Modules, forming a layer of abstraction that simplifies process design and execution.

An Equipment Module might manage a section of a production line or a specific unit operation, like mixing or heating, by coordinating the actions of various Control Modules. It can perform a sequence of actions to complete tasks, such as establishing flow paths for materials or accurately dosing components according to a recipe. This modularization enhances system robustness and scalability, as you can integrate new Equipment Modules into the process with minimal disruption.

Phase

A Phase represents a discrete task within a process sequence, defined by a specific goal or outcome. It is a dynamic entity that captures the process logic necessary to transform raw materials or intermediates into a product or to change the state of the process.

Phases can be composed of steps and transitions that guide the process flow, dictating actions based on process conditions and operator inputs. They can interact with other phases, Equipment Modules, and Control Modules to synchronize process activities. Phases ensure that each segment of the process is performed according to defined procedural standards, allowing for consistent execution and quality control.

Operation

An Operation is a higher-order function that strings together multiple Phases into a cohesive process narrative. It delineates a major segment of the production sequence, guiding the process through a series of state changes, each marked by distinct Phase actions. Operations are typically defined by the transformations they achieve—such as mixing, fermenting, or separating—each requiring a choreographed set of Phases that progress the material toward the desired state, be it a change in composition, temperature, or physical form.

Procedure

At the apex of the ISA-88 structure, the Procedure defines the overarching strategy for executing a batch or continuous process. It is a macro-level blueprint that outlines the sequential Operations required to produce a final product from start to finish.

Procedures are the master recipes that process engineers and operators follow, ensuring that each batch or process run adheres to the specified quality and operational parameters. By structuring the process into Procedures, the approach provides clarity and control over the manufacturing process, enabling consistent execution and facilitating compliance with regulatory requirements.

These components work in concert to provide a comprehensive framework for managing and executing complex manufacturing processes, ensuring that each element, from the individual control of equipment to the strategy of batch execution, is optimized for efficiency, consistency, and quality.

Bringing it all Together

A significant advantage of using modular coding is the abstraction of recipe configuration from the PLC layer, manageable in any HMI/SCADA platform. This allows process engineers to manage processes independently, without relying on control engineers.

Avoiding Spaghetti Code Can Transform Automation Complexity

Returning to our spaghetti metaphor, we see a clear parallel in our professional world. In our kitchens, spaghetti signifies a familiar, satisfying meal. In coding, especially in PLCs, we aspire to avoid the ‘spaghetti’ mess in favor of something more structured and palatable.

Modular coding in PLCs is akin to a well-prepared dish: organized, efficient, and effective. It’s like having a recipe that’s easy to follow and adjust, always yielding a delightful result in performance, scalability, or maintenance. Modular coding transforms the complexity of automation into something as straightforward and pleasing as a family dinner. Just as no one desires a tangled mess on their plate, the same goes for our code. Modular coding ensures that our professional creations are as appealing as what we’d serve at our dinner tables.