Why you shouldn’t use your Building Management System as your Environmental Monitoring System

You might be wondering, since I already have a Building Management System (BMS), why can’t we just use that for an Environmental Monitoring System (EMS) as well? While it may seem like a convenient option at first glance, a deeper look at the capabilities of each system reveals that relying solely on a BMS for comprehensive monitoring and compliance might not be the wisest choice.

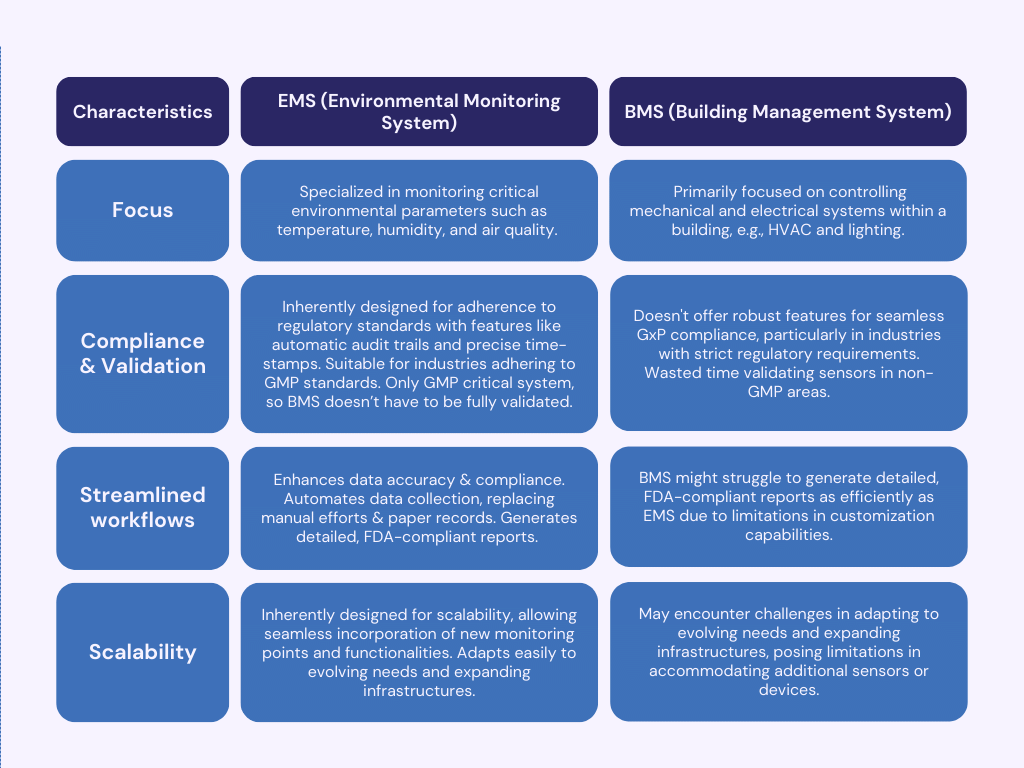

BMS vs EMS

Firstly, it’s crucial to understand the distinct functions of each system. A Building Management System (BMS) focuses on controlling and optimizing building systems like HVAC, lighting, security, and fire alarms. Its main goal is to maintain occupant comfort, energy efficiency, and operational efficiency within the building.

In contrast, an Environmental Monitoring System (EMS) is designed to monitor and record environmental parameters. This includes data from BMS sensors, but also extends to other sensors outside the BMS scope. Additionally, an EMS focuses on ensuring compliance with regulatory requirements.

Critical Reasons for Choosing a Dedicated EMS

This misalignment becomes even clearer when we delve into the nuanced and specialized functionalities that an EMS brings to the table. Now, let’s explore further reasons why a dedicated EMS is crucial for optimal environmental management.

- Equipment & Sensor Focus:

Focusing on granular control and precise data acquisition, environmental monitoring systems (EMS) differ starkly from their building management system (BMS) counterparts. BMS primarily oversee HVAC and lighting systems for occupant comfort, whereas EMS delve into the minutiae of critical equipment and environmental parameters in scientific or heavily regulated environments.

While a BMS might monitor basic temperature and humidity, an EMS meticulously tracks specialized equipment like bioreactors and incubators, ensuring their optimal operation within stringent ranges of air quality, purity, and even vibration. This oversight extends beyond the confines of traditional buildings, safeguarding sensitive processes even in remote locations lacking a central BMS. As such, EMS play a crucial role in industries where upholding meticulous environmental standards is paramount to ensuring operational efficiency and product integrity.

- Compliance & Validation:

Regulatory compliance, especially in industries adhering to Good Manufacturing Practice (GMP) standards, particularly in the context of FDA CFR Part 11 compliance, demands meticulous monitoring and documentation of environmental conditions. BMS systems don’t offer the robust features required for seamless GxP compliance. An EMS, inherently designed for adherence to regulatory standards, includes functionalities like automatic audit trails and precise timestamps, ensuring transparency and accountability in regulated industries. Additionally, utilizing a separate EMS eliminates the need for full validation of your BMS, reducing the requirement to validate sensors in non-GMP areas.

- Streamlined workflow:

An EMS transforms data acquisition, reporting, and alarm response, from labor-intensive chores into a seamless, efficient flow. Manual readings and paper logs become relics of the past, replaced by automated, continuous data capture with secure, timestamped records. Comprehensive reports are generated autonomously, aggregating data from various sources and presenting it in readily digestible, FDA-compliant formats. Proactive insights replace reactive alarm systems, notifying personnel of potential deviations before they escalate, enabling swift interventions and minimizing costly disruptions.

This translates to significant time savings for employees, freeing them from tedious tasks to dedicate their expertise to higher-value activities like data analysis and process optimization. By implementing a validated EMS, your team gains invaluable time, enhances data accuracy, and fosters peace of mind, ensuring effortless compliance with regulatory requirements.

- Future-Proofing for Scalability:

Unlike Building Management Systems (BMS), which may encounter challenges in adapting to evolving needs and expanding infrastructures, Environmental Monitoring Systems (EMS) are inherently designed for scalability. The rigid architecture of many BMS may pose limitations when it comes to accommodating additional sensors, devices, or the integration of new technologies. In contrast, EMS solutions are characterized by their flexibility and ease of scalability, allowing seamless incorporation of new monitoring points and functionalities.

This adaptability ensures that as facilities grow or undergo modifications, the environmental monitoring infrastructure can effortlessly scale to meet the expanding requirements. By choosing a separate EMS, organizations not only address their current environmental monitoring needs but also future-proof their systems, laying the foundation for a scalable and agile approach to facility management in the ever-evolving landscape of technological advancements and operational expansions.

Why You Need a Separate EMS

While the BMS excels in managing building infrastructure, it is evident that stretching it for environmental monitoring poses challenges that can significantly impact facility compliance, validation, streamline workflows, and long-term adaptability. Understanding the strengths and limitations of each system is key. An EMS, designed for the specific demands of environmental monitoring, not only ensures regulatory compliance but also promotes optimal efficiency and adaptability in facility operations.

As you consider your facility’s needs, we invite you to explore our case study on how we assisted a leading regenerative medicine company in achieving seamless GMP compliance.

Interested in discovering more about implementing a dedicated Environmental Monitoring System?

Head over to our EMS product page for an in-depth exploration of the features and benefits that can enhance your facility’s environmental monitoring capabilities

January 2, 2024

January 2, 2024

December 2, 2025

December 2, 2025