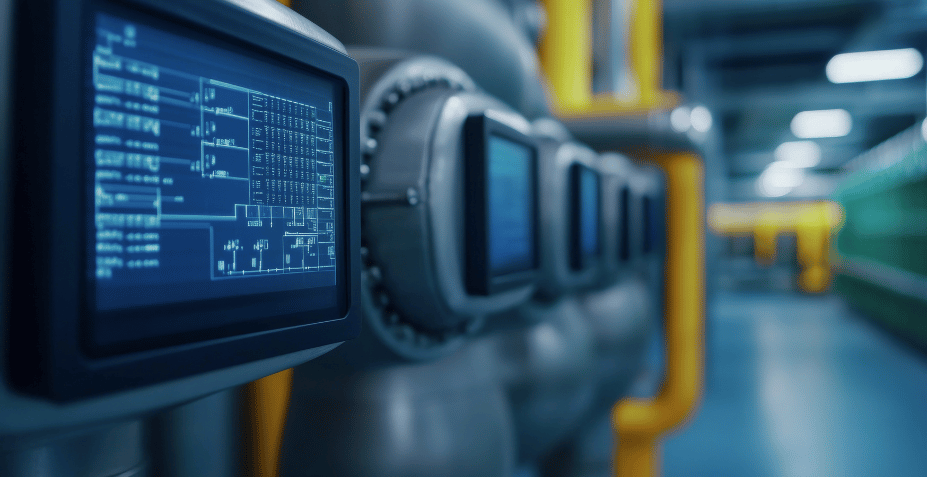

Traditional Overall Equipment Effectiveness (OEE) provides historical data on equipment performance, measuring factors such as availability, performance, and quality. While useful, OEE primarily offers a retrospective view of manufacturing operations. Alternatively, Manufacturing Asset Performance Management (APM) enhances OEE by providing real-time dashboards and insights, building on historical data with current operational visibility.

Advances in industrial automation technology have transformed manufacturing asset management, enabling data to be presented with greater context and actionable insights in order to meet high priority goals, such as cycle time reduction and throughput improvement. Read More

We’re excited to announce that Andrew DeChirico, NeoMatrix’s Engineering Manager, has been selected as one of Control Engineering‘s 2024 Engineering Leaders Under 40! This prestigious recognition celebrates Andy’s exceptional leadership, technical expertise, and the significant impact he has made in the industrial automation industry. Read More

We’re excited to announce that Andrew DeChirico, NeoMatrix’s Engineering Manager, has been selected as one of Control Engineering‘s 2024 Engineering Leaders Under 40! This prestigious recognition celebrates Andy’s exceptional leadership, technical expertise, and the significant impact he has made in the industrial automation industry. Read More

NeoMatrix was honored to receive the Inductive Automation 2024 Firebrand Award for our efforts in aiding Lucid Motors along its digital transformation journey leveraging Ignition. Read More

This article was originally published on AutomationWorld.com on July 15, 2024.

For companies in regulated industries, such as life sciences, properly managed alarm notification systems are key to quality assurance.

Life science companies must adhere to the FDA’s Good Manufacturing Practices (GMP) in manufacturing and storage of the product within their manufacturing facility. For example, GMP compliance is required for a bioreactor process and for any product storage in a freezer room. GMP ensures that each step of the manufacturing process is conducted under controlled conditions, with appropriate documentation, data records and quality checks at each stage. Read More

We’re excited to announce that

We’re excited to announce that