Ensuring the Effective Execution of Production Operations and Improving Performance

Every manufacturing organization performs several functions to operate on a day-to-day business. Many of these functions are covered by software systems such as Enterprise Resource Planning (ERP), Quality Management Software (QMS), Computerized Maintenance Management Systems (CMMS) and automated control systems at the plant floor. The gap between these manufacturing systems has historically been filled by Manufacturing Enterprise Systems (MES) or Manufacturing Operations Management (MOM) systems.

Whether you use the term MES, MOM, or Enterprise Integration, the goal of these systems is to help fill the gaps in an existing manufacturing software stack between backend business functions and plant floor control. Functions such as production control and scheduling, maintenance, quality control, and inventory are commonly handled by home grown systems with Microsoft Excel or Microsoft Access, or even paper-based tracking systems. Adopting an enterprise integration strategy provides many benefits:

- More timely, accurate, and data accessibility to improve decision making.

- Reduction of data entry and redundant data entry resulting in increased labor effectiveness and accuracy of data.

- Sharing of data and automated transactions between disparate business systems.

- Increasing production repeatability and adherence to customer specifications.

- Enhancing effectiveness by increasing production time, performance, and quality.

- Improved product and production traceability to help adhere to regulatory guidelines.

- Reduction of paper on the plant floor.

Developing an Enterprise Integration Strategy

A classic dilemma with MES systems is whether to implement a Commercial Off the Shelf (COTS) system or build a homegrown solution. The optimum solution is often somewhere in between as there really is not a COTS MES system that fits a manufacturers specific needs and there is always some level of advanced configuration or customization required. An effective enterprise integration strategy will consider the existing business processes and systems and deploying a platform which is:

- Based on industry standards and provides documented and open APIs for bi-directional transfer of data.

- Modular allowing for cost effective implementation with the possibility for expansion.

- Easily configured and maintained by operations personnel.

- Supported by an ecosystem of partners who can help implement a solution.

NeoMatrix has extensive experience with the leading MES vendors and can help architect a solution and road map to build an effective enterprise integration strategy taking into consideration your existing software stack, budget, and timelines.

Simplifying Production Scheduling

Production scheduling can be quite complex in the manufacturing world. ERP systems often do not have the granularity required to implement a full production schedule to the asset level due to the complexities of having an abundance of part numbers and routing requirements. Having access to real-time information with regards to delays, scheduling changes and down equipment often throws off production schedules.

Due to this fact, schedulers often use tools like Microsoft Excel to generate schedules and update them weekly, daily, or even on a shift-by-shift basis. NeoMatrix has the experience to make this process easier, less time consuming and hassle free by:

- Pulling work orders directly from the ERP system.

- Scheduling work order operations at the equipment level with a drag and drop interface.

- Giving real-time feedback on production status and updating the existing schedule to account for any production delays.

- Scheduling downtime on the equipment for preventative maintenance or R&D trials.

- Providing visibility to the schedule throughout the enterprise in a web-based format.

Automating Recipe Management

Manufacturing recipes define machine settings required to produce a product on a specific production line. While this information is typically stored within a process of record, some processes have hundreds of set points to configure. Manually transcribing those values costs valuable time for your operations staff and is very prone to error – opening the possibility to having more scrap and rework. An electronic recipe system allows for an operator to simply scan the part number being made and having the machine setpoints automatically populate.

Recipe management is a daunting task for manufacturers with thousands of part numbers. Utilizing a parent child hierarchy, managing thousands of part numbers becomes a much easier task. Changes to recipes can be propagated across an entire product family rather than one part number at a time.

Revision control is required for manufacturers in regulated industry companies who have implemented a quality management system. Tracking who, when, and what changes were made should be an inherent part of any recipe management system.

Improvements with Overall Equipment Effectiveness(OEE)

Monitoring industrial processes and uncovering opportunities to help you do more with your existing resources requires an OEE solution. The OEE calculation is comprised of three loss factors:

- Availability losses are unplanned equipment downtime.

- Performance losses are when equipment is running at less than target speeds.

- Quality losses occur when product does not meet quality specifications.

Evaluating these losses can provide engineering, maintenance, and operations teams direction as to which areas to focus improvement initiatives. Modern OEE platforms can connect to your automation system and automatically collect this information from your automation systems. Automatic data collection reduces data entry error and provides more time for your team to analyze the data and start improving your processes.

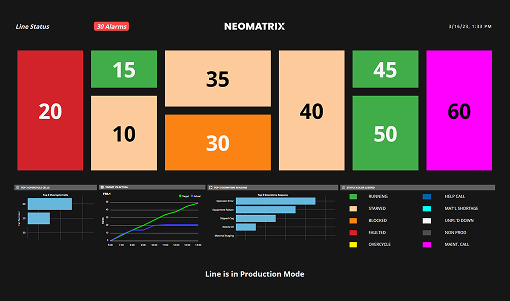

Optimizing Manufacturing Processes with Andon Boards

Andon Boards are a visual management tool often used in lean manufacturing that can help you make smarter, faster real-time decisions to improve your bottomline. Andon displays show the real-time status of your manufacturing processes, including information about equipment, production lines, and workers’ performance. They detect production issues in real-time and help operations teams take immediate action to resolve them, resulting in increased output and reduced costs.

OT Asset Discovery and Recovery

With multiple industrial automation solutions and systems designed by different vendors and delivered over a wide range of time, routine maintenance and backups are often overlooked or unidentified, leaving manufacturers' OT assets vulnerable.

Platforms We Support

Experience Matters.

Neomatrix is the expert in implementing MES in a variety of industries and processes.