Supplemental PLC Training Classes

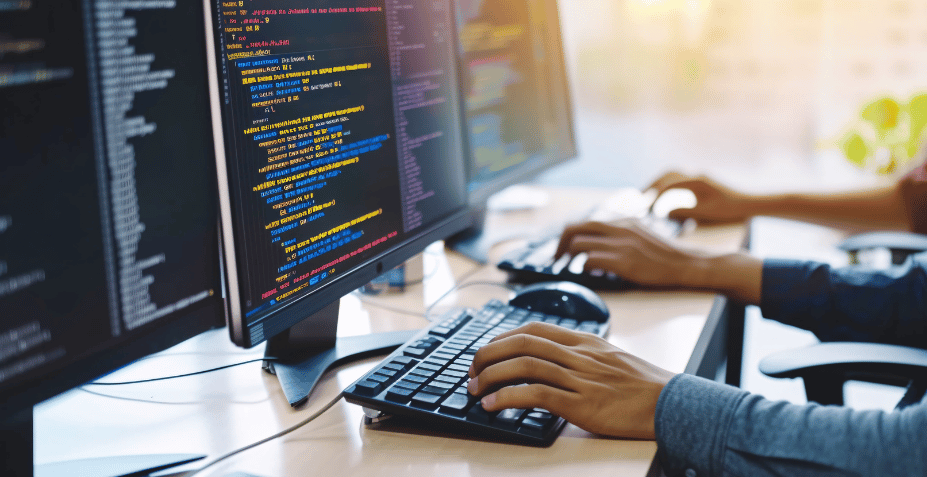

While Programmable Logic Controllers (PLC) platform provider training offers a strong foundation, the focus is on the vendor-specific PLC itself and its basic operational skills. NeoMatrix’s supplemental training goes beyond these basics and creates PLC classes that are customized to support your plant's holistic operational requirements.

PLC Training Focus: Basics and Fundamentals

1. PLC Hardware & Components

We’ll review your specific PLC hardware and components, their functions, and how they work together in your plant. Then we’ll create a customized syllabus for effective PLC programming and maintenance. We’ll include:

Types of PLCs: Our PLC trainers will review the different types of PLC classifications based on size, functionality, and "to support your plant's holistic operational requirements."

Basic PLC Architecture: Our trainers will go over the core components of your PLC system, including the central processing unit (CPU), input/output (I/O) modules, power supply, and communication interfaces.

Basic PLC Structure: Our PLC course will cover your PLC’s scanning cycle, program execution, and communication between the CPU and I/O modules.

2. PLC Software

Basic PLC Software Structure: Provides an overall context of how to properly structure a PLC based control system regardless of PLC type, programming language or platform.

3. PLC Programmable Language

Since no two plants are designed the same, our PLC training is tailored to the particular programming languages you employ at your facility. Our PLC training courses are specifically designed to give your engineers and technicians the skills they need to program and manage the PLCs in your plant, regardless of whether your PLCs use the more sophisticated options like function block diagrams or the more common language of ladder logic.