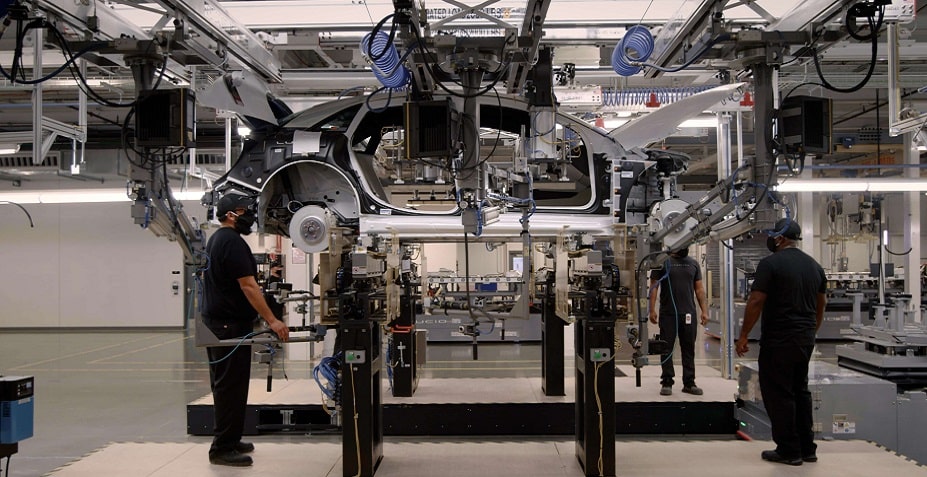

Today's automotive manufacturers are competing for market share and strategically rely on the ability to make quick, data-driven decisions, easily optimize and scale manufacturing processes, and continually improve overall operational performance. However, one of the largest bottlenecks these manufacturers face is aggregating all of their data across the enterprise, including PLC and MES data sources, into a single place from which they can make real-time decisions.

NeoMatrix specializes in designing and integrating industrial automation solutions that allow for comprehensive monitoring of manufacturing operations, providing real-time visibility and insights into production efficiency, quality, and inventory management.

Benefits of Automation in the Automotive Industry

- Increase Efficiency and Productivity:

Improved precision, consistency and speed on the assembly line helps manufacturers reduce production time to meet demand. - Improved Quality Control:

Consistent quality control quickly identifies defects or deviations from the required specifications to minimize waste/production down time. - Cost Reduction:

Reduced reliance on human labor minimizes the risk of errors and rework, reducing cost and waste. - Flexibility and Adaptability:

Automated systems allow manufacturers to introduce new models, make design changes, or adjust production volumes more efficiently. - Supply Chain Optimization:

Automation assists with inventory management, material handling, logistics, and order fulfillment, improving overall efficiency and reducing lead times. - Data Collection and Analysis:

Performance monitoring, predictive maintenance, and process optimization enable continual process improvement.

The Value NeoMatrix Brings to Automation in the Automotive Industry

NeoMatrix works with leading automotive manufacturers to help them stay competitive in a rapidly evolving industry. Some of the critical information NeoMatrix can put at your fingertips to enable smarter and faster decision-making across the manufacturing enterprise includes:

- Line status overviews:

These give a real-time view of the status of production lines, enabling prompt action to address any issues or bottlenecks and minimize production disruptions - Real-time monitoring of OEE:

This identifies areas for improvement and implementing corrective measures to optimize production performance. - Quality Issue Alerts:

Identifying product quality issues early in the production process allows for timely corrective actions and reduced scrap or rework. - Monitoring and trending of jobs per hour (JBH) PH or cycle time:

Providing insights into the productivity and efficiency of the production process over time. - Production loss editor:

Allows for noting reasons for not achieving production targets, categorizing them into machine, man, material, or method-related issues. This function helps identify root causes of production losses, implementing corrective actions, and continuously improving production processes. - Open and closed defects for each vehicle by line:

Providing detailed information on defects for each vehicle by line allows for effective defect tracking, analysis, and resolution. This reporting helps identify patterns or trends in defects, implementing corrective measures, and improving overall product quality.

Leaders in Creating More Efficient and Profitable Automotive Manufacturing Factories

Leading with our client-first approach for over 20 years, NeoMatrix has developed a proven process that helps automotive manufacturers design, implement and sustain factory automation systems and MES solutions that improve operational efficiencies and reduce manufacturing costs.