Evolving consumer trends demand that food and beverage manufacturers quickly adapt to and produce high-quality products, all while maintaining profitability goals and ensuring product safety within a strictly regulated environment.

Food and beverage automation solutions can provide the agility and flexibility needed to meet today’s consumer demands and support the requirement for effective traceability systems throughout the supply chain.

Benefits of Automation in the Food and Beverage Industry

With food and beverage manufacturers continually navigating volatile market conditions, such as changing consumer preferences and economic fluctuations, adaptability, agility, and proactive planning are a must. Implementing automation and technology solutions can help improve efficiency and reduce costs by:

- Maintaining food safety;

- Streamlining production processes;

- Reducing waste; and

- Optimizing inventory management.

The Value NeoMatrix Brings to Food and Beverage Automation Solutions

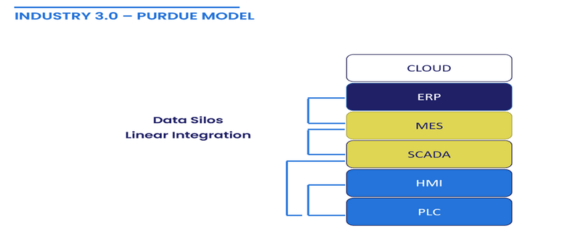

Implementing food and beverage automation solutions requires careful planning, customization, and integration with existing systems. When you partner with Neomatrix, we utilize a proven process for helping you assess your specific needs and determine the most valuable factory automation solutions that can propel your operations forward.

Some of the automation solutions we provide include:

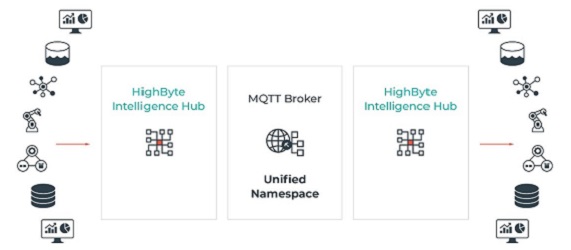

- Process Automation: Implementing innovative software solutions to streamline workflows, improve accuracy, and reduce reliance on human intervention.

- Packaging and Labeling Automation: Improving the speed and accuracy of packaging processes to reduce labor requirements and increase output.

- Automated Conveyor and Material Handling Systems: Enabling efficient movement of raw materials, ingredients, and finished products to optimize product flow and reduce manual handling.

- Quality Control and Inspection Systems: Identifying inconsistencies, foreign objects, and packaging errors to reduce the risk of product recalls and waste.

- Process Control and Monitoring Systems: Real-time monitoring of critical parameters such as temperature, pressure, pH, and flow rate. These systems can automatically adjust process parameters to ensure consistency and adherence to specifications.

- Batch Management and Recipe Systems: Automated batch management systems streamline recipe management, ingredient scaling, and process sequencing.

- Energy Management Systems: Monitoring and controlling energy consumption, identifying energy-saving opportunities, and optimizing energy usage during production.

- Traceability and Recall Management Systems: Enabling rapid identification and removal of affected products, minimizing the impact on consumers and brand reputation.

- Data Analytics and Reporting: Gaining insights into production performance, quality trends, inventory levels, and customer demand.

Leaders in Creating More Efficient and Profitable Food and Beverage Automation Solutions

Leading with our client-first approach for over 20 years, NeoMatrix has developed a proven process that helps food and beverage manufacturers design, implement and sustain factory automation systems and MES solutions that improve operational efficiencies and reduce manufacturing costs.