In an era where the manufacturing industry is rapidly shifting towards digitalization, it is crucial to stay updated on the latest technologies and compliance requirements that can drive this digital transformation. Manufacturers in the life sciences and pharmaceutical industries regularly use Ignition by Inductive Automation in applications requiring 21 CFR Part 11 given the company’s commitment to enabling customer success with regulated applications.

I’m sharing the following guide by Inductive Automation that addresses building FDA 21 CFR Part 11 applications using Ignition. This guide helps provide relevant industry background and demonstrates how Ignition and standard technologies can create compliant applications. An especially important theme is Inductive’s advocacy for a mutual responsibility model among all key constituents – the customer, software vendors, and Ignition system integrators.

If you’re familiar with regulatory compliance, the guide’s Compliance Summary Table provides a quick glance at the features within Ignition and highlights the application design aspects that need to align with organizational guidelines. The Compliance Detailed Description offers step-by-step advice on how to adhere to the regulations.

If you are new to 21 CFR Part 11, I suggest starting from the beginning of this guide, as it offers helpful foundational information.

Understanding the FDA 21 CFR Part 11

The FDA 21 CFR Part 11 is a cornerstone in the domain of electronic records and electronic signatures as it sets the standards that manufacturers must meet for their electronic records and signatures to be considered legally and functionally equivalent to their traditional paper counterparts. This equivalence is crucial in manufacturing’s digital age, where electronic data management is the norm.

The FDA 21 CFR Part 11 regulation is not just a guideline but a requirement, ensuring that electronic data management systems in the pharmaceutical industry meet the stringent requirements of trustworthiness, reliability, and equivalence to traditional records. The regulation also lays out requirements for software functionality, including audit trails and system validation, to ensure transparency and integrity of the data. While navigating through this regulation may seem challenging, understanding its importance in safeguarding data integrity and maintaining trust in electronic systems can guide manufacturers in implementing robust digital strategies compliant with these requirements.

21 CFR Part 11-Compliant Application Using Ignition Software Case Studies

Environmental Monitoring System in Pharmaceutical Industry for Meeting FDA GMP Compliance:

A leading regenerative medicine company created a GMP and 21 CFR Part 11-compliant application using Ignition software and Rockwell ControlLogix hardware utilizing the PlantPAx architecture. > READ THE CASE STUDY

Helping Customers with 21 CFR Part 11 Software Provides FDA Compliance for Pharma:

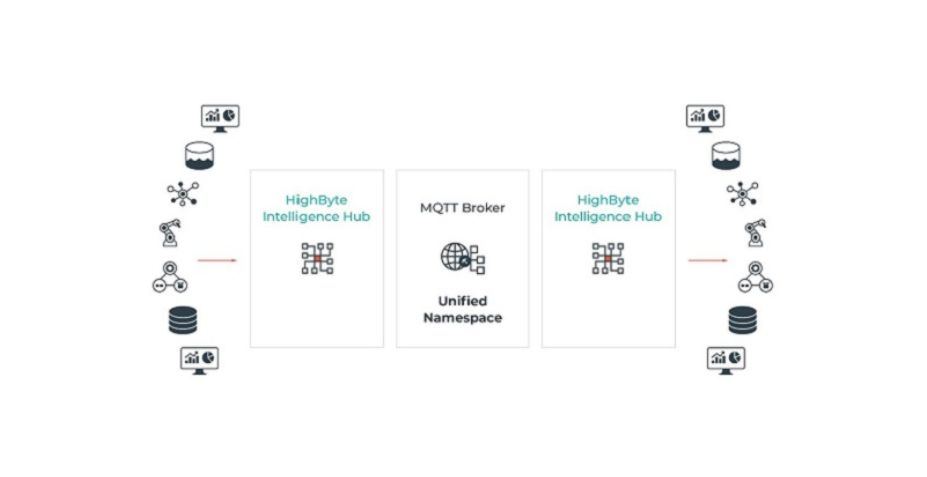

Snapdragon Chemistry adopted an Ignition SCADA system to achieve 21 CFR Part 11 compliance. > READ THE CASE STUDY

Partnering for Manufacturing Excellence & Compliance

Together with Inductive Automation, we aim to empower manufacturers in life sciences and the pharmaceutical industries and simplify the journey towards digital transformation while ensuring strict adherence to compliance guidelines such as 21 CFR Part 11 and GAMP.

As a Premier Ignition Integrator, we aid manufacturers in making strategic decisions, identifying potential roadblocks, and developing robust systems to meet their goals and support their regulatory compliance.

February 21, 2024

February 21, 2024

June 23, 2025

June 23, 2025