Customized Training on Rockwell Allen Bradley Software

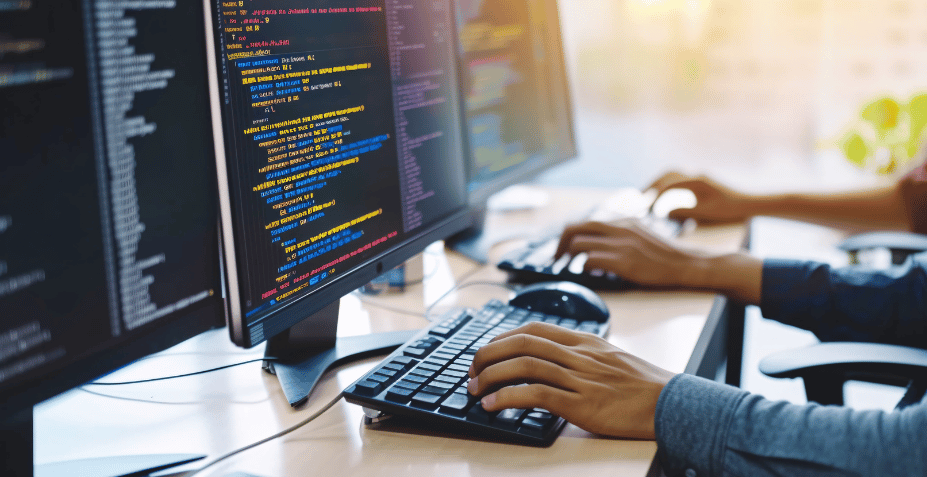

The most evident foundations for success in today's manufacturing operations are superior technology and tools. However, this isn’t the whole picture. These tools need operators who understand how to effectively manage, analyze, and troubleshoot in order to drive a successful plant.

We understand this and, as an experienced Rockwell Automation System Integrator, have developed comprehensive courses for supplemental Rockwell Automation training. Our training classes cover Rockwell hardware such as ControlLogix®, CompactLogix®, and MicroLogix® PLCs, along with Rockwell Software including FactoryTalk programming tools for logic development, FactoryTalk View for HMI (Human-Machine Interface) creation, and PlantPAx DCS for complex process control applications.

Our customized Rockwell training creates learning paths specifically designed for your industry, meaning courses cover equipment, processes, and challenges unique to your sector. Develop specialized skills for your sector, allowing you to: