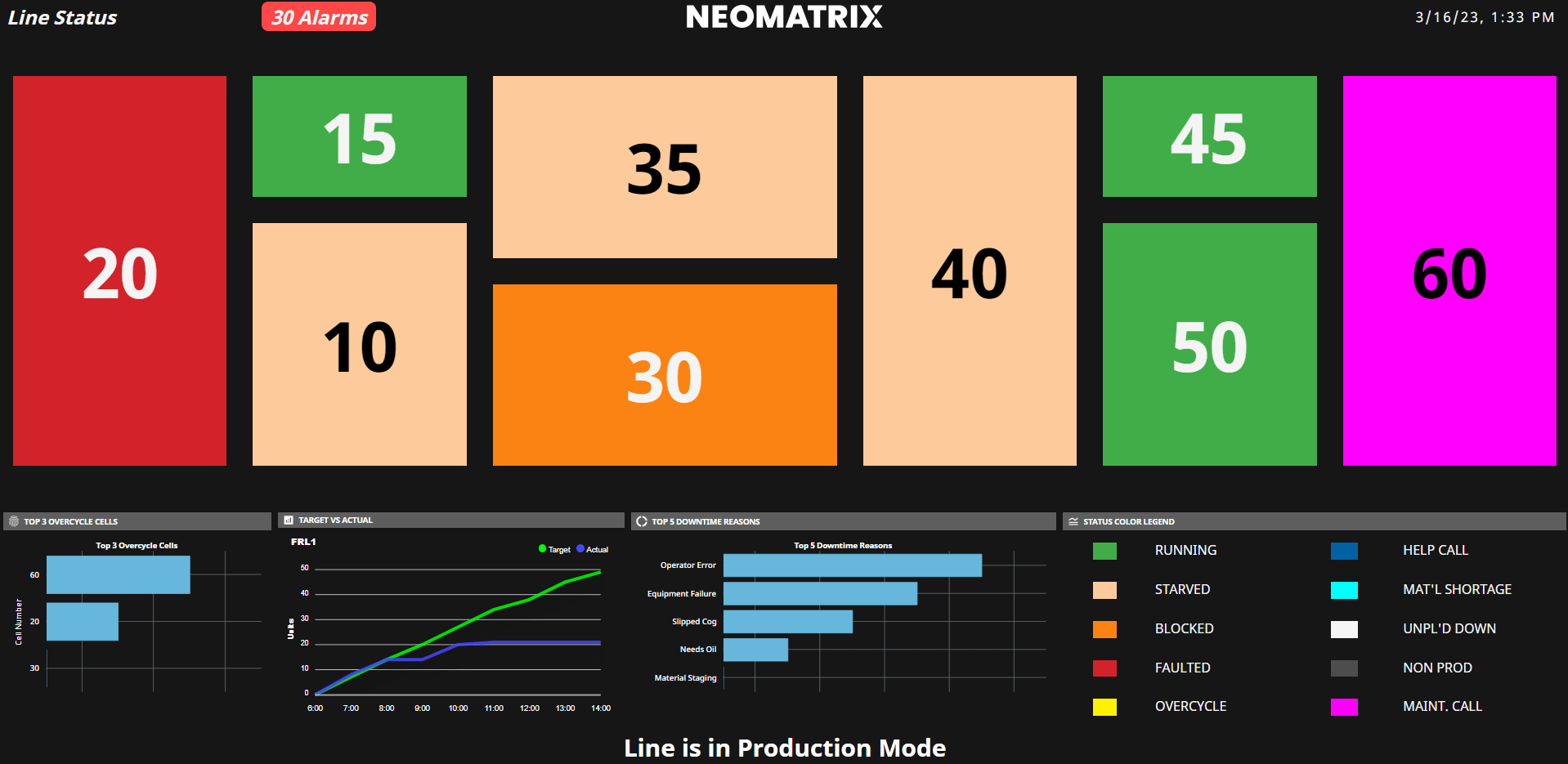

Make smarter, faster real-time decisions to improve your bottomline

Andon Boards are a visual management tool, often used in lean manufacturing, that displays the real-time status of your manufacturing processes, including information about equipment, production lines, and workers’ performance. They detect production issues in real-time and help operations teams take immediate action to resolve them, resulting in increased output and reduced costs.

Benefits of Andon Boards in Manufacturing

Quicker response time to critical issues such as:

Machine downtime

Part shortages & material-handling issues

Operator help requests

Improved accountability, transparency & collaboration:

Real-time feedback on performance vs target

Workers gauge performance against their colleagues