In the ever-evolving landscape of industrial control systems (ICS), the Purdue Model has long been a standard for architecting these systems. However, as technology advances and the Industrial Internet of Things (IIoT) rises in significance, the Unified Namespace (UNS) architecture has become increasingly prominent.

The Purdue Model: A Hierarchical Legacy

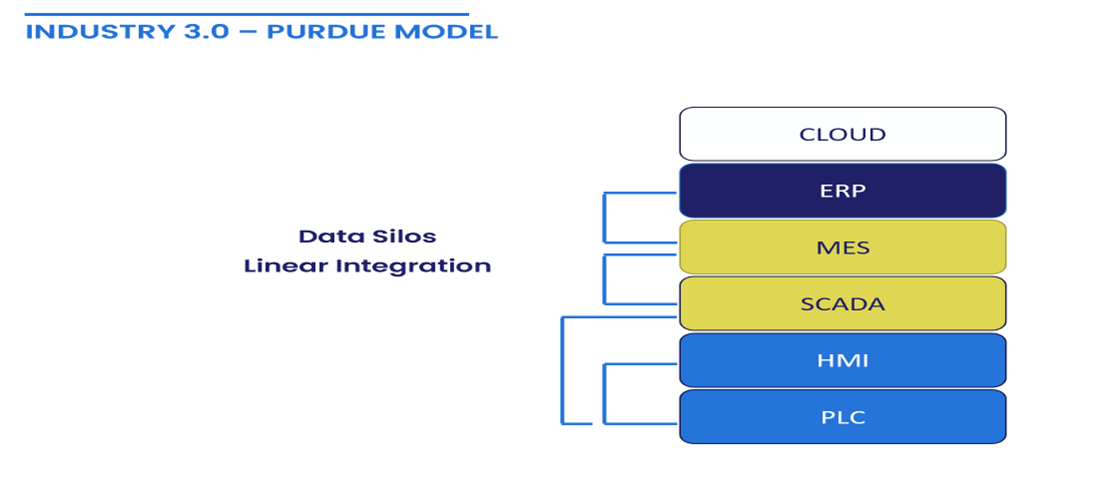

The Purdue Model, initially introduced as the Purdue Enterprise Reference Architecture in the 1980s, has been a staple in providing a hierarchical structure for industrial communications. Its layers, ranging from Level 0 (sensors and actuators) to Level 5 (enterprise systems), have guided the organization of industrial control systems for years. The model’s influence even extends to standards like ISA-95, defining the interface between enterprise and control systems.

Challenges with the ICS Purdue Model

While the Purdue model has been instrumental in organizing industrial control systems, with its structured approach to data flow and communication, it’s not as well-suited for the dynamic landscape of Industry 4.0. The rise of IIoT, edge computing, and cloud technologies necessitates a different architectural approach. These advancements introduce new architectures that are superior to the model’s vertical hierarchy.

For example, consider a scenario where data from sensors at Level 0 needs to communicate directly to an enterprise system at Level 5. This means many 1:1 connections between the technology stack and each level, each having its own set of technologies, protocols, and interfaces, making the integration process complex. The IIoT era accentuates this challenge, where a more interconnected and horizontal flow replaces the traditional vertical flow of data.

To address this there is an acknowledgement that manufacturers need a more flexible and adaptable approach. This is where concepts like Unified Namespace (UNS) come into play, offering a way to integrate diverse systems without sacrificing the benefits of segmentation and structure provided by the Purdue Model.

Unified Namespace: Flattening the Landscape of Industrial Control Systems

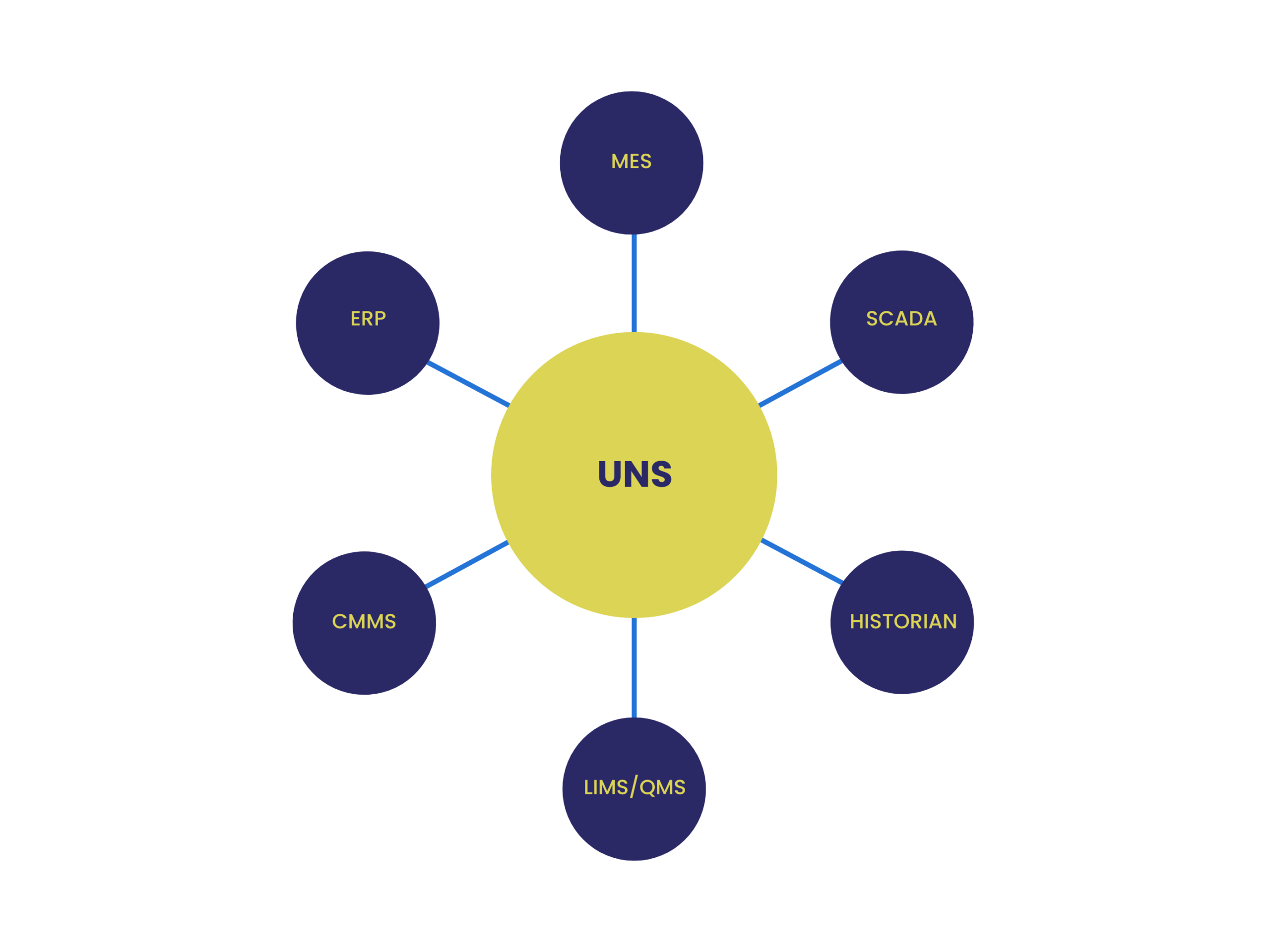

Unlike the traditional ICS Purdue Model with its segregated layers, UNS introduces a more modern architecture that fosters a flatter, more agile, and interconnected network. This departure from the rigid hierarchical structure of the Purdue Model allows for more agility and facilitates the integration of plant floor devices, manufacturing technology, and business systems into a singular comprehensive view of data across the entire system.

In essence, Unified Namespace architecture not only flattens the landscape of Industrial Control Systems but also paves the way for a more connected, responsive, and collaborative future where all devices and systems converse in a common “language” in the realm of industrial automation.

Adopting a Unified Namespace strategy eliminates the common issues tied to data silos and stagnant data in traditional integration approaches. By breaking down these barriers, UNS facilitates a seamless exchange of information, ensuring data flows freely throughout the entire system.

The removal of strict hierarchical layers in UNS supports communication and collaboration across previously isolated layers. Using a Unified Namespace allows you to integrate each individual tool to the Unified Namespace directly.

Now, to get the data from a PLC to the ERP system, you only need to make one hop from the Unified Namespace — instead of three as in a traditional integration. This allows devices at any layer to directly communicate with one another without following a predefined vertical path.

Benefits of UNS Architecture:

- Standard Presentation of Data – even when underlying data has a different structure.

- Simplified Integration – enabling the easy onboarding of new data sources and applications.

- Reduced Costs – only one communication interface vs. multiple point-to-point connections.

- Improved Agility – real-time data gives manufacturers the ability to improve their processes.

Choosing the Right Approach for Your Needs

Selecting the optimal architecture for your industrial control system is contingent upon your specific requirements. While the Purdue Model for ICS remains suitable for particular scenarios, the Unified Namespace offers a compelling alternative for those seeking agility, real-time insights, and scalable data integration. The future may even see the emergence of a hybrid approach, combining the strengths of both models to create a truly efficient and adaptable industrial system.

To delve deeper into the key concepts and features of a Unified Namespace, read our blog titled “What is UNS?”

March 28, 2024

March 28, 2024

November 18, 2025

November 18, 2025